Here at CooperVision, we’re taking steps in our manufacturing and distribution to operate more sustainably where possible. We are striving to eliminate waste and unnecessary packaging to reduce our environmental impact.1

Through our Sustainability Innovator Series, we'll share stories of people in a wide range of roles throughout our global organization who contribute to our environmentally sustainable efforts, big and small.

Learn more about our partnership with Plastic Bank and meet the innovators at CooperVision who helped make it a reality.

Our teams at CooperVision are taking steps to reduce plastic’s carbon footprint.*2,3 By exploring ways to transform the way plastic is made and helping to prevent plastic’s diversion into nature,†4 we’re reimagining what’s possible for plastic.

Meet some of the minds behind this work and see what inspires us to evolve toward a brighter tomorrow.

Aldo Zucaro serves as CooperVision’s sustainability champion - identifying and uncovering new sustainability opportunities and strategies that help to decrease CooperVision’s footprint.

Paul Riggs plays a crucial role in progressing our sustainability efforts across CooperVision and around the world, as he strives to find areas in which to minimize our possible environmental impact and support People + Planet.

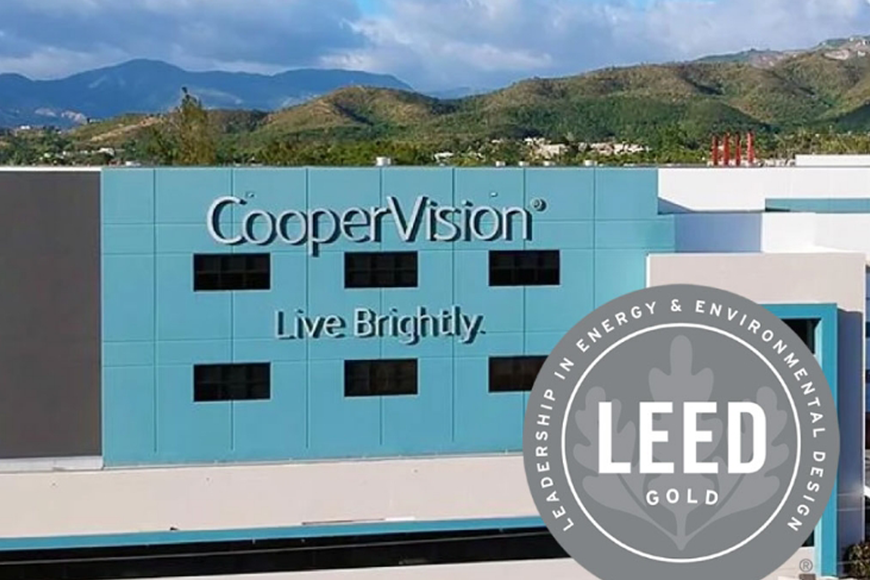

From conservation efforts in Puerto Rico, to earning LEED Gold certification in Costa Rica, and receiving a BREEAM certified “Excellent” rating in the United Kingdom, we’ve been recognized for our ongoing dedication to sustainability in the many places we do business.

A brighter tomorrow starts with all of us, today.

* According to peer-reviewed papers, polypropylene (PP) made using renewably sourced inputs yields a lower carbon footprint. CooperVision's plastic supplier has found that manufacturing PP using fossil-based inputs produces 1.63 kg CO2e/kg PP whereas manufacturing PP using plant-based inputs produces -0.82 kg CO2e/kg PP.

† Refers to CooperVision's plastic neutrality initiative with Plastic Bank. Plastic neutrality is established by purchasing credits from Plastic Bank. A credit represents the collection and conversion of one kilogram of plastic that may reach or be destined for waterways. CooperVision purchases credits equal to the weight of plastic in our-one day contact lens orders. One-day contact lens plastic is determined by the weight of plastic in the blister, the lens and the secondary package (outer carton), including laminates, adhesives, and auxiliary inputs (e.g. ink).

References::

1. CVI data on file, 2024.

2. CVI data on file, 2023. Cradle-to-gate assessment of renewable bio input carried out by our supplier of plastic polymer to CooperVision.

3. Narayan, R. (2011). Carbon footprint of bioplastics using biocarbon content analysis and life-cycle assessment. MRS Bulletin, 36(09), 716-721. https://doi.org/10.1557/mrs.2011.210.

4. CVI data on file, 2023.